Vehicle Crash Testing

Vibration Testing

Amusement Ride Testing

Fully Programmable

Versatile

Accurate

Extremely Reliable

Extremely Rugged

Flexible

Simple to use

Works in Real Time

Manual Trigger Box

Trigger Plug

AC Power Adaptor

NiMH Battery Packs

Accelerometers

String Pots

Photo Proximity Sensors

Gear Tooth Sensors

DataBRICK3 Data Acquisition System

The DataBRICK3 provides reliable, high performance data acquisition in a compact, rugged package. Designed for use in highly dynamic environments, like vehicle crash testing, the DataBRICK3 is also an excellent choice for most other test applications where a robust, precision data acquisition system is needed.

Each DataBRICK3 is a complete data acquisition system. Plug in your sensors and a nominal 12 VDC power source and you are ready to go - no need to buy extra cards or modules. The included Windows software makes setup straightforward for tests of all sizes and configurations.

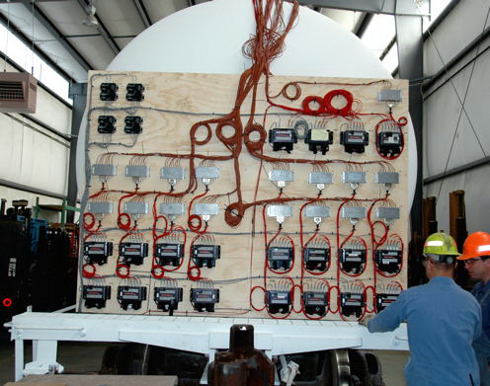

The DataBRICK3 is versatile. Use one unit for a small test or multiple units for larger tests. Multiple DataBRICK3’s can be mounted together in a rack or distributed to keep them in close proximity to your sensors.

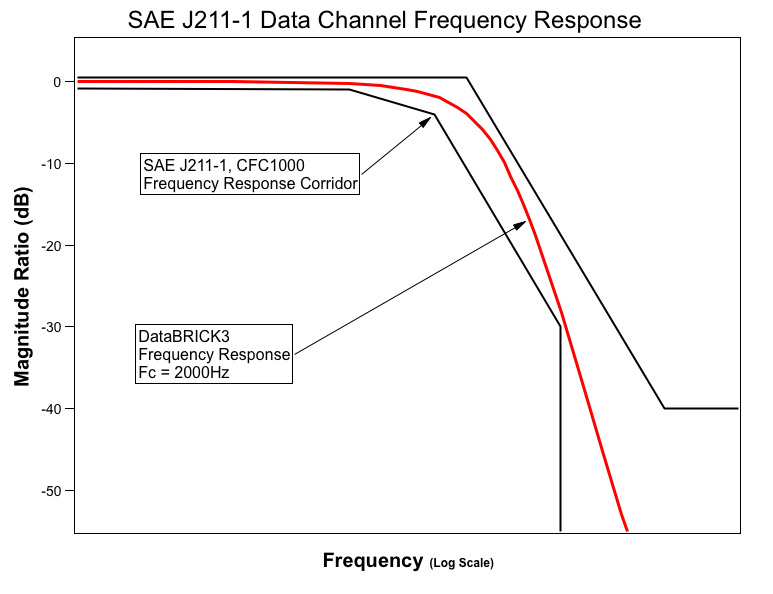

The DataBRICK3 is accurate. With quality components and low noise circuitry, the DataBRICK3 provides up to 14 bit resolution. Programmable anti-aliasing filters prevent data distortion.

The DataBRICK3 is rugged. A billet aluminum case, engineered component supports, and precision push-pull connectors all combine to create a package that’s guaranteed to function flawlessly with accelerations up to 200 g.

The DataBRICK3 is flexible. Most sensors can be accommodated with its 8 analog and 4 counter channels. Each analog channel may be configured for sample rate, gain, excitation voltage, low-pass filter, and input offset. Several trigger settings allow combinations of pre-trigger sampling, multiple trigger events, and triggering from an analog channel.

The DataBRICK3 is cost effective. Compare the cost and performance of a DataBRICK3 to other systems and discover the great value it provides.

|

|

|

|

The above pictures were taken while NASA was doing research and development for the International Space Station's emergency escape pod. A DataBRICK2 was used to measure velocity and g forces on a test article. The test article was dropped from an altitude of 10,000 feet. It struck the desert floor at well over 500 miles per hour. In the first picture on the left, NASA is using dynamite to break through the desert hard pan to retrieve the buried test article and instrumentation. In the next picture, NASA is using a tractor to dig down to the equipment. In the third picture, a man, at the bottom of the hole, is hand digging to retrieve the DataBRICK2. In the last picture, on the right, is the recovered DataBRICK2. The DataBRICK2 was damaged, but we were able to recover the data for NASA. The new DataBRICK3 is even more rugged. Can your data acquisition system withstand that kind of abuse?

|

|

|

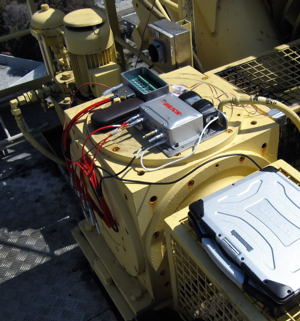

A locomotive ready for crash testing using DataBRICK data acquisition systems and a Hybrid III anthropomorphic test dummy. |

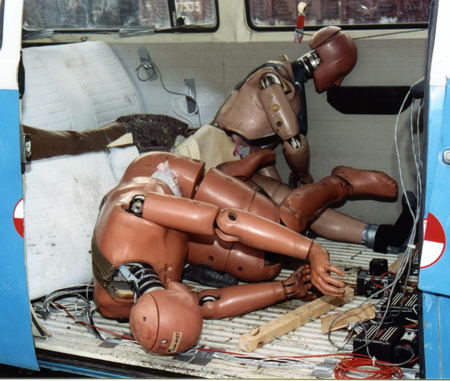

Aftermath of a crash test in a van using rugged DataBRICK data loggers and Hybrid III anthropomorphic test dummies. |